Edge Computing Control System for Intelligent Compressed Air Stations

Smart Energy Management • Industrial IoT • Reliable Air Supply

In modern manufacturing plants, compressed air is often referred to as the “fourth utility”. However, inefficient operation, unstable pressure, excessive energy consumption, and high maintenance costs remain common challenges in traditional compressed air stations.

This article introduces an Edge Computing–based Intelligent Compressed Air Station Control System, designed to improve energy efficiency, operational reliability, and management transparency through industrial automation and IoT technologies.

Concept of an Intelligent Compressed Air System

The intelligent compressed air system is built around the principles of energy saving, efficiency improvement, and green manufacturing. Through coordinated multi-machine control and standardized system architecture, the solution stabilizes air pressure, improves air quality, reduces energy consumption, and lowers overall maintenance costs.

Goal: Deliver high-quality compressed air with the lowest possible lifecycle cost, supporting sustainable and intelligent factory operations.

Why Edge Computing?

The system adopts an edge computing control architecture, executing critical logic locally to ensure millisecond-level response, high reliability, and strong data security.

- Real-time control with low latency

- Stable operation independent of network availability

- Enhanced data security and privacy protection

- Seamless cloud and enterprise system integration

Core Functions at a Glance

- Unattended station operation

- Real-time equipment monitoring

- Automatic alarm and fault notification

- Pressure-based start/stop control

- Balanced runtime strategy

- Custom start-up priority logic

- Scheduled operation by production plan

- Automatic load/unload adjustment

- Standby rotation and backup switching

- Maintenance reminder management

System Architecture

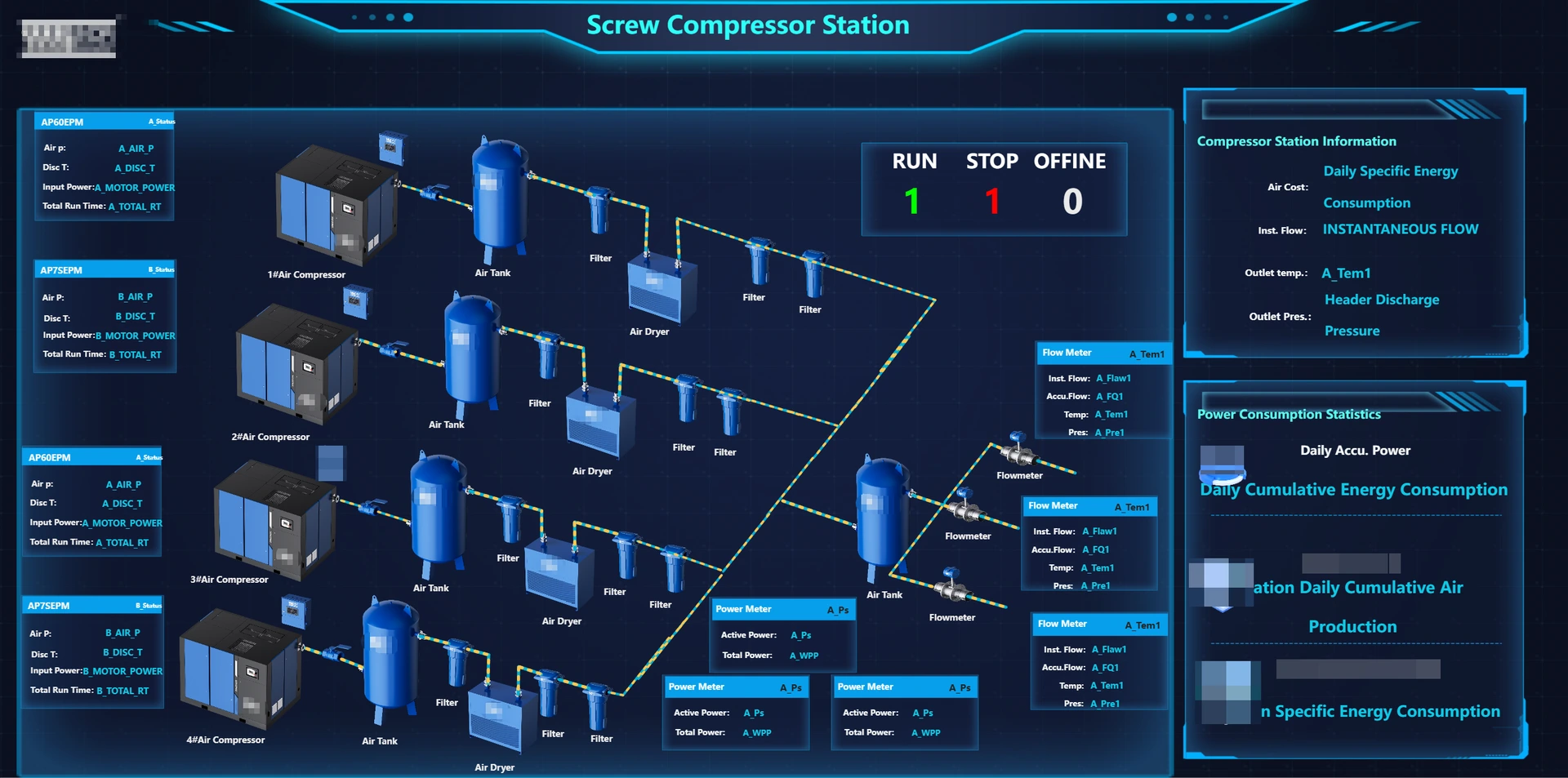

Compressors, dryers, flow meters, pressure sensors, and power meters are connected to an industrial edge controller via reliable wired industrial networks.

All control logic runs locally at the edge, while operational data is synchronized with upper-level platforms for visualization and analysis.

Monitoring & Data Platform

- 2D / 2.5D system dashboards

- Up to 3 years of historical data storage

- Flexible time-based trend analysis

- Custom alarm thresholds and notifications

- Energy efficiency and cost analysis

- Gas–electricity correlation analysis

Intelligent Group Control Strategy

The system supports local, manual, and fully automatic control modes. In automatic mode, compressors are dynamically managed based on pressure, flow demand, and runtime balance.

Conclusion

By combining edge computing, industrial automation, and intelligent control strategies, this solution transforms traditional compressed air stations into efficient, reliable, and data-driven energy systems.

It enables manufacturers to reduce energy consumption, stabilize air supply, extend equipment lifespan, and move closer to a truly intelligent factory.

Edge Computing Control System for Intelligent Compressed Air Stations

Smart Energy Management • Industrial IoT • Reliable Air Supply

In modern manufacturing plants, compressed air is often referred to as the “fourth utility”. However, inefficient operation, unstable pressure, excessive energy consumption, and high maintenance costs remain common challenges in traditional compressed air stations.

This article introduces an Edge Computing–based Intelligent Compressed Air Station Control System, designed to improve energy efficiency, operational reliability, and management transparency through industrial automation and IoT technologies.

Concept of an Intelligent Compressed Air System

The intelligent compressed air system is built around the principles of energy saving, efficiency improvement, and green manufacturing. Through coordinated multi-machine control and standardized system architecture, the solution stabilizes air pressure, improves air quality, reduces energy consumption, and lowers overall maintenance costs.

Goal: Deliver high-quality compressed air with the lowest possible lifecycle cost, supporting sustainable and intelligent factory operations.

Why Edge Computing?

The system adopts an edge computing control architecture, executing critical logic locally to ensure millisecond-level response, high reliability, and strong data security.

- Real-time control with low latency

- Stable operation independent of network availability

- Enhanced data security and privacy protection

- Seamless cloud and enterprise system integration

Core Functions at a Glance

- Unattended station operation

- Real-time equipment monitoring

- Automatic alarm and fault notification

- Pressure-based start/stop control

- Balanced runtime strategy

- Custom start-up priority logic

- Scheduled operation by production plan

- Automatic load/unload adjustment

- Standby rotation and backup switching

- Maintenance reminder management

System Architecture

Compressors, dryers, flow meters, pressure sensors, and power meters are connected to an industrial edge controller via reliable wired industrial networks.

All control logic runs locally at the edge, while operational data is synchronized with upper-level platforms for visualization and analysis.

Monitoring & Data Platform

- 2D / 2.5D system dashboards

- Up to 3 years of historical data storage

- Flexible time-based trend analysis

- Custom alarm thresholds and notifications

- Energy efficiency and cost analysis

- Gas–electricity correlation analysis

Intelligent Group Control Strategy

The system supports local, manual, and fully automatic control modes. In automatic mode, compressors are dynamically managed based on pressure, flow demand, and runtime balance.

Conclusion

By combining edge computing, industrial automation, and intelligent control strategies, this solution transforms traditional compressed air stations into efficient, reliable, and data-driven energy systems.

It enables manufacturers to reduce energy consumption, stabilize air supply, extend equipment lifespan, and move closer to a truly intelligent factory.

Frequently Asked Questions (FAQ)

Q1: What problems does an edge computing control system solve in a compressed air station?

It addresses common issues such as unstable air pressure, excessive energy consumption, inefficient multi-compressor coordination, delayed fault response, and lack of operational transparency. By executing control logic locally, the system ensures fast response and stable air supply.

Q2: How is edge computing different from a cloud-only compressed air monitoring system?

Edge computing executes critical control logic locally at the site, while cloud-only systems rely heavily on network connectivity. Even if the network is unavailable, the edge-based system continues to operate safely and reliably.

Q3: Can this system work with compressors from different brands?

Yes. The system supports multi-brand and multi-model compressors, as long as they provide standard industrial interfaces such as Modbus RTU, Modbus TCP, or dry contact signals.

Q4: Does the system support both fixed-speed and variable-speed compressors?

Yes. The control strategy supports mixed operation of fixed-speed and variable-speed compressors, automatically optimizing load distribution to keep equipment operating in the most energy-efficient range.

Q5: How does the system help reduce energy consumption?

Energy savings are achieved through pressure stabilization, intelligent start/stop control, runtime balancing, elimination of unloaded running, and detailed energy efficiency analysis based on real operating data.

Q6: Is the system suitable for small or medium-sized factories?

Yes. The system is scalable and modular. Small factories can start with basic monitoring and control functions, and later expand to advanced analytics and cloud integration as needed.

Q7: What happens if a compressor fails during operation?

When a major fault occurs, the system automatically skips the faulty unit and starts a standby compressor to maintain stable air pressure and prevent production interruption.

Q8: Can the system integrate with existing MES, SCADA, or energy management platforms?

Yes. The edge controller provides standard industrial communication interfaces, allowing seamless data integration with MES, SCADA, ERP, or enterprise energy management systems.

Frequently Asked Questions (FAQ)

Q1: What problems does an edge computing control system solve in a compressed air station?

It addresses common issues such as unstable air pressure, excessive energy consumption, inefficient multi-compressor coordination, delayed fault response, and lack of operational transparency. By executing control logic locally, the system ensures fast response and stable air supply.

Q2: How is edge computing different from a cloud-only compressed air monitoring system?

Edge computing executes critical control logic locally at the site, while cloud-only systems rely heavily on network connectivity. Even if the network is unavailable, the edge-based system continues to operate safely and reliably.

Q3: Can this system work with compressors from different brands?

Yes. The system supports multi-brand and multi-model compressors, as long as they provide standard industrial interfaces such as Modbus RTU, Modbus TCP, or dry contact signals.

Q4: Does the system support both fixed-speed and variable-speed compressors?

Yes. The control strategy supports mixed operation of fixed-speed and variable-speed compressors, automatically optimizing load distribution to keep equipment operating in the most energy-efficient range.

Q5: How does the system help reduce energy consumption?

Energy savings are achieved through pressure stabilization, intelligent start/stop control, runtime balancing, elimination of unloaded running, and detailed energy efficiency analysis based on real operating data.

Q6: Is the system suitable for small or medium-sized factories?

Yes. The system is scalable and modular. Small factories can start with basic monitoring and control functions, and later expand to advanced analytics and cloud integration as needed.

Q7: What happens if a compressor fails during operation?

When a major fault occurs, the system automatically skips the faulty unit and starts a standby compressor to maintain stable air pressure and prevent production interruption.

Q8: Can the system integrate with existing MES, SCADA, or energy management platforms?

Yes. The edge controller provides standard industrial communication interfaces, allowing seamless data integration with MES, SCADA, ERP, or enterprise energy management systems.

Contact Us

We'd love to hear from you! Whether you have questions, feedback, or need support, our team is here to help. Simply fill out the form below, and we aim to respond to all inquiries within 24 hours. Thank you for getting in touch!